Prototyping and Tooling

⇀ Multipul Material Selection

⇀ Low-To-High Volume Production

⇀ Instant Quotes & DFM Support

From Prototype to Production

Teamsworld offers complete services of prototyping and mold-making, which are crucial steps in the early-stage design process. With a good understanding of these technologies and their differences, Teamsworld helps customers reduce errors, accelerate part design validation, and lower costs associated with mass production. Additionally, Teamsworld provides Design For Manufacturing (DFM) support to increase flexibility in the design process, leading to faster time to market for customers.

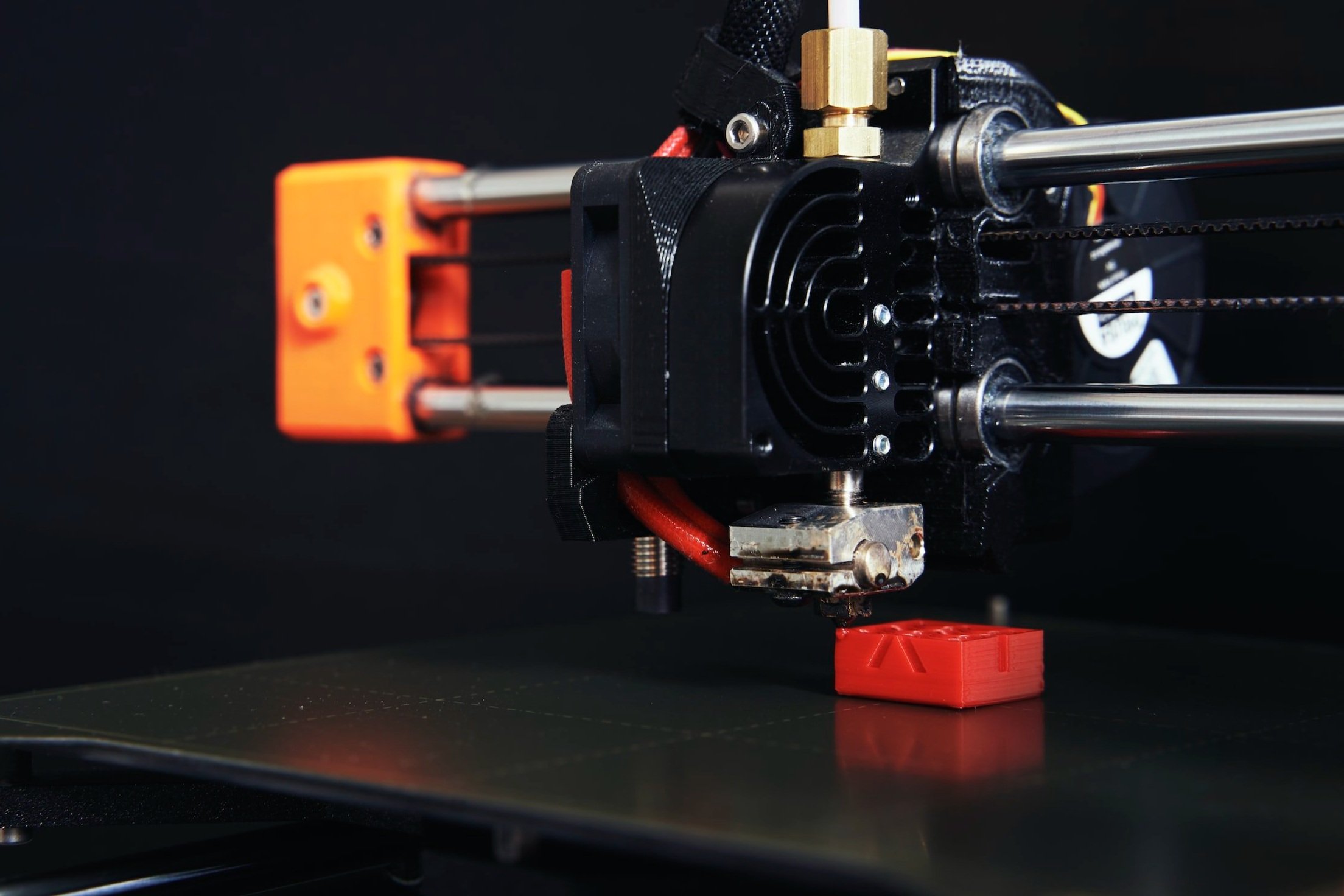

Prototyping

Prototyping is the process of creating a preliminary model or sample of a product or part before mass production. Various methods can be employed, including 3D printing, CNC machining, and injection molding. Prototyping offers several advantages, including greater flexibility in the design process, and is particularly useful for part design validation, low-volume production, and bridge production quantities.

Tooling

Mold making, or production tooling, is the process of creating a tool or mold that can be used for the large quantities of the product or part with consistent quality. Mold-making offers several advantages, including the ability to produce high volumes of products efficiently, cost-effectively, and with consistent quality. It can also reduce lead times and help to minimize errors and waste, leading to greater efficiency and profitability.

Unlock Innovation Together

→

Manufacturability Feedback

Simply provide your drawing in 2D/3D format to get instant quote and manufacturability feedback with our 24/7 service.100% data protection for every design.

Early-design Support

With free Design for Manufacturing (DFM) support, you can easily simplify the product design, optimize the manufacturing process and speed up the time to market.

Material Selection

The suitable material selection for an industry-specific application is conducted by comparing the material characteristics, and the requirement profile in detail. Thus, your design can easily achieve its desired functionality, safety, and service life.

More Manufacturing Services

Die Casting

Die-casting is a versatile, reliable, and accurate manufacturing process that can produce complex metal parts at high volumes. It eliminates most secondary operations and can meet tight tolerances without post-machining.

Investment Casting

With high accuracy and little need for machining, investment casting can help save time, and cost and reduce processing errors by eliminating welding and assembly to produce a wide variety of complex parts made with different metals and alloys.

Gravity Casting

Gravity casting results in smoother surfaces and dimensional accuracy, when producing high-volume, quality casts with minimal finishing required. With reusable molds, it can produce aluminum and zinc castings in a sustainable way.

Thermoforming

Thermoforming, known for its fast and economical tooling/mold, becomes the ideal option for producing plastic parts with excellent production-grade repeatability, and the ability to produce large custom-designed parts in low to medium volumes at a lower cost.

LSR Injection Molding

Also known as Liquid Silicone Rubber Injection Molding. It’s a highly efficient manufacturing process that utilizes liquid silicone to produce high-quality LSR injection-molded parts with several benefits, including high and low-temperature resistance, low compression set, and excellent electric properties.

Injection Molding

Injection molding, a versatile and cost-effective method for producing plastic components of various sizes and complexities, is capable of accurately dealing with small features, intricate geometries, and thin walls. Moreover, Injection molding offers various material selections and surface finishing options.

Why Teamsworld ?

Customer-Centric

Culture

Think ahead and consider the customer’s needs in every aspect from DFM support to product inspection.

Cloud-based

Project Management

Strengthen manufacturing transparency for both customers and factories with optimized communication efficiency.

Sustainability-oriented

Innovation

More than the focus on the cost, time and quality, Teamsworld steps to lower carbon emissions and reduce waste under sustainable thinking.