A360 Aluminum: Applications, Characteristics, and Future Trends

A360 Aluminum is a specialized aluminum alloy that has become a material of choice in various industries due to its unique combination of properties. As industries continue to evolve, seeking materials that align with modern technological advancements and sustainability goals, A360 Aluminum stands out as a versatile and future-focused alloy.

This article explores the characteristics, applications, advantages, limitations, and future trends of A360 Aluminum, providing a comprehensive insight into its role in shaping contemporary manufacturing and design. The following sections delve into the specific aspects that define A360 Aluminum's significance in today's industrial landscape.

What Is A360 Aluminum?

A360 Aluminum is a specific type of aluminum alloy known for its exceptional fluidity and resistance to hot cracking. As part of the number 3 series of aluminum alloys, A360 is primarily composed of aluminum, silicon, and other trace elements. The presence of silicon significantly enhances its casting characteristics, making it a preferred choice for various casting processes.

Historically, A360 Aluminum has been utilized in industries where high thermal and electrical conductivity is required. Its unique composition allows for excellent machinability, corrosion resistance, and surface finish. Compared to other aluminum alloys, A360 offers a balanced combination of mechanical properties and ease of production.

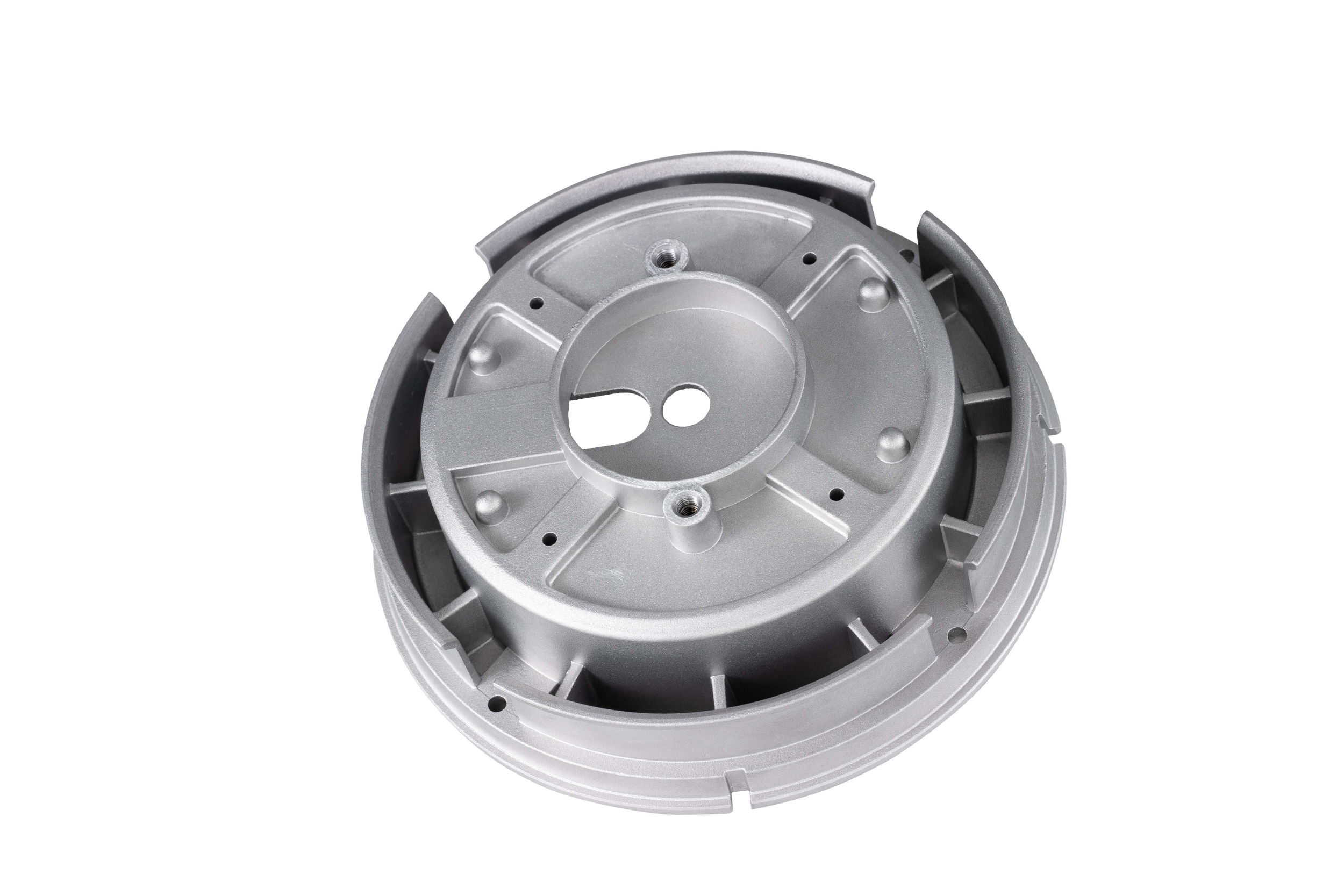

One of the distinguishing features of A360 Aluminum is its adaptability to die casting, gravity casting, and other molding techniques. This adaptability makes it suitable for complex shapes and thin-walled components, often used in automotive, lighting, and technologies.

Advantages of A360 Aluminum

1. Mechanical benefits

A360 Aluminum is renowned for its excellent mechanical properties, including high tensile strength, hardness, and resistance to wear and corrosion. These attributes make it suitable for applications that require durability and reliability, such as automotive parts and components of technology products.

2. Economic benefits

The alloy's adaptability to different casting methods, such as die casting and gravity casting, allows for cost-effective production. Its ease of machining and ability to be formed into complex shapes reduces manufacturing costs, making it an economically viable option for mass production.

3. Environmental benefits

A360 Aluminum is environmentally friendly due to its recyclability. Unlike some other materials, it can be melted down and reused multiple times without losing its essential properties. This contributes to sustainability and reduces the environmental impact of manufacturing processes.

A360 Aluminum Applications

A360 Aluminum is a versatile material with a wide range of applications across various industries. Its unique properties make it suitable for different production processes and end-use applications.

Aluminum Alloy Part Production

A360 Aluminum's adaptability to different casting methods is one of its standout features:

Die Casting: Die casting is a process where molten A360 Aluminum is forced into a mold cavity under high pressure. This method is ideal for producing complex shapes with high precision. A360's excellent fluidity and resistance to hot cracking make it a preferred choice for die casting, resulting in parts that are both strong and aesthetically pleasing.

Gravity Casting: In gravity casting, A360 Aluminum is poured into a mold and allowed to solidify under the force of gravity. This process is simpler and less expensive than die casting, making it suitable for producing larger parts. A360's unique composition ensures a smooth surface finish and robust mechanical properties.

Automotive applications

In the automotive industry, A360 Aluminum is used extensively for its strength-to-weight ratio and corrosion resistance. It's commonly found in engine components, transmission parts, and structural elements of vehicles. Its lightweight nature contributes to fuel efficiency, while its durability ensures long-lasting performance.

Lighting applications

A360 Aluminum's thermal conductivity and malleability make it a sought-after material in the lighting industry. It's commonly used in the housings for LED lights, as well as in heat sinks that dissipate heat from the bulbs, enhancing their lifespan. Its corrosion resistance also means that these components won't deteriorate quickly, even in outdoor or industrial settings. The metal's light weight allows for easy installation and portability, making it particularly useful in modular lighting systems.

Applications in technology products

In the realm of technology products, A360 Aluminum offers both aesthetic and functional advantages. The material's smooth finish is visually appealing, often used in the casing of laptops, smartphones, and other electronic devices. Functionally, its thermal properties make it efficient for cooling internal components, contributing to optimized performance and extended device longevity. Additionally, its structural strength makes it ideal for creating durable frames for servers and other heavy-duty tech equipment.

A360 Aluminum Application Limitations

While A360 Aluminum is valued for its versatility, it has limitations. Technically, it may not suit applications requiring extreme hardness or high-temperature resistance. Environmentally, its recycling process can be energy-intensive, and raw material extraction may raise ecological concerns. Economically, specialized treatments can increase costs, limiting their viability in budget-sensitive projects. Additionally, compatibility issues with certain chemicals or materials may restrict its use. Understanding these limitations is vital for selecting A360 Aluminum in alignment with specific application requirements.

Characteristics of A360 Aluminum

A360 Aluminum is a prominent aluminum alloy with distinct characteristics that make it suitable for various applications. Its mechanical properties, physical properties, and composition contribute to its widespread use.

A360 Aluminum Mechanical Properties

Tensile Strength: A360 Aluminum exhibits high tensile strength, allowing it to withstand significant stretching without breaking. This property makes it ideal for parts that must endure heavy loads and stresses.

Hardness: The hardness of A360 Aluminum contributes to its wear resistance, making it suitable for components that are subject to friction and abrasion, such as gears and bearings.

Elasticity: A360's elasticity enables it to return to its original shape after deformation, a crucial factor in applications requiring flexibility and resilience, such as springs and flexible connectors.

Fatigue Resistance: This alloy's resistance to fatigue ensures that it can endure repeated cycles of stress without weakening. This characteristic is vital in dynamic applications like automotive suspension systems.

A360 Aluminum Physical Properties

Density: A360 Aluminum's relatively low density makes it lightweight, contributing to its use in applications where weight reduction is essential, such as lightingand automotive industries.

Melting Point: With a melting point suitable for various casting methods, A360 Aluminum can be molded into complex shapes, enhancing its applicability in intricate designs.

Thermal Conductivity: Its high thermal conductivity makes A360 Aluminum an excellent conductor of heat, suitable for heat exchangers, radiators, and other thermal management components.

Electrical Conductivity: A360's electrical conductivity enables its use in electrical applications, including wiring and electrical connectors, where efficient electrical energy transmission is required.

A360 Aluminum Composition

Elemental Composition: A360 Aluminum is primarily composed of aluminum and silicon, with trace amounts of other elements. The silicon enhances its casting characteristics, while other elements can modify specific properties.

Alloying Elements: Various alloying elements can be added to A360 Aluminum to tailor its properties for specific applications. Common alloying elements include magnesium, copper, and zinc.

Impurities and Their Effects: Impurities in A360 Aluminum can affect its properties, either positively or negatively. Controlled addition or removal of certain impurities can optimize its characteristics for particular uses.

Future Trends: Development Trends of A360 Aluminum

A360 Aluminum is poised for growth across various industries, aligning with modern technological needs and sustainability.

Automotive Industry: A360 Aluminum's lightweight nature, strength, and conductivity make it essential for fuel efficiency, electric vehicles, and durable components. Its application in the automotive sector is expected to grow with the trend toward greener transportation.

Lighting Industry: In the lighting industry, A360 Aluminum's thermal conductivity and aesthetic appeal are driving its use in energy-efficient and visually pleasing lighting solutions. Its role in prolonging LED lifespan underscores its growing importance.

Information and Communication Industry: A360 Aluminum's versatility, electrical conductivity, and shielding capabilities align with the information and communication industry's trend towards miniaturization and high-performance computing. Its suitability for connectors and enclosures in communication devices emphasizes its relevance.

A360 Aluminum's unique properties and versatile applications make it a vital material in various industries. Its role in the automotive, lighting, and technology sectors highlights its adaptability and future potential. Understanding its characteristics and trends can unlock new opportunities for innovation and efficiency. If you're interested in exploring how A360 Aluminum can enhance your projects or need expert guidance, our team is here to help. Contact us today to discover the possibilities that A360 Aluminum offers for your specific needs.